Concrete brick making machine production line

1.Way of moulding is vibration combined with hydraulic pressure.So blocks have good strength and density.The machine can produce hollow block,solid block,paving block by changing mould.

2.The way of concrete feeding into mould is compulsive by three shaft with blades.It is quick speed and well distributed.The vibration is oil-immersed to have a good lubrication.

3.Only two vibration motors is always working,other motors works fitfully.So it is power saving.

4.Concrete feeder,pallet feeder,up mould and down mould is powered by hydraulic system.

5.Mould is made with heat treatment,Carburizing.So working life of mould is improved.

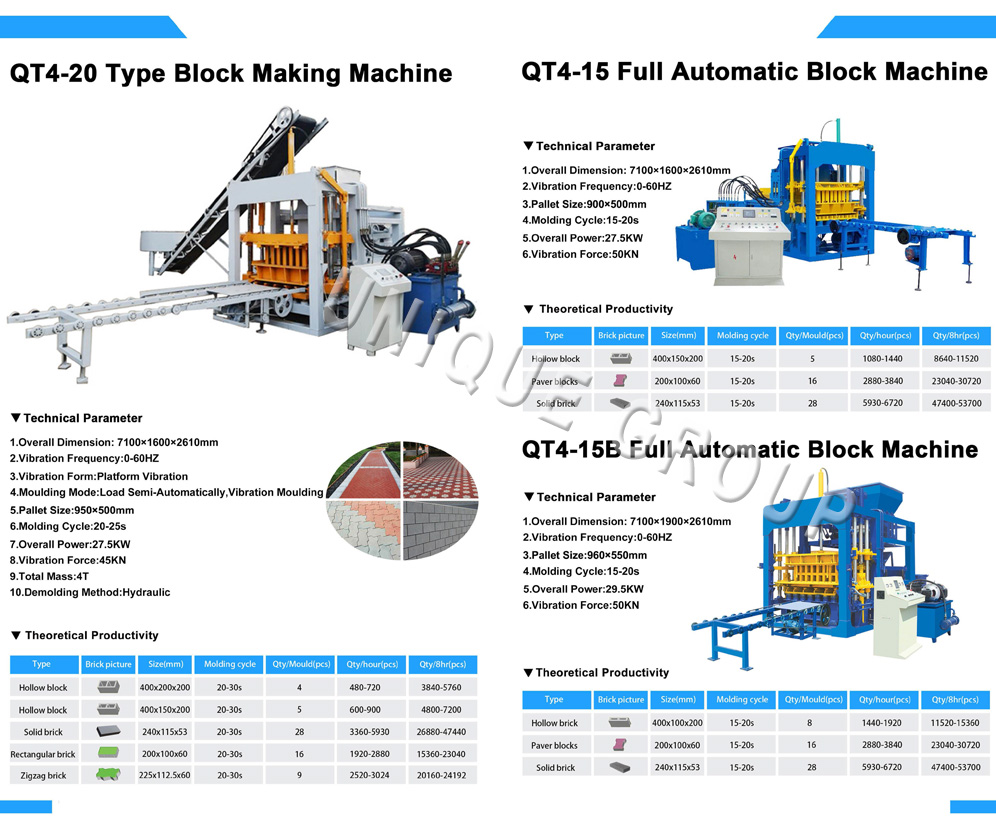

| Type | Molding cycle(s) | Pallet size (mm) | Overall power(kw) | Overall dimension |

| QT6-15 | 15-25 | 900x700 | 31.25 | 9400X2460X2880 |

| QT5-15 | 15-20 | 1100x550 | 30.5 | 7400X1950X2800 |

| QT4-5Type | Size(mm) | Molding cycle | Qty/Mould(pcs) | Qty/hour(pcs) | Qty/8hr(pcs) |

| Hollow block | 400x150x200 | 15-205 | 6 | 1080-1440 | 8640-11520 |

| Paver blocks | 200x100x60 | 15-20s | 16 | 2880-3840 | 23040-30720 |

| Solid brick | 240x115x53 | 15-20s | 28 | 5930-6720 | 47400-53700 |

Copyright © 2025 UNIQUE GROUP | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.

Product Message