Features of high frequency core mold vibration pipe making machine:

①Low amplitude, high frequency (5000-6000rpm), large excitation force, high compactness of the components, and basically no pores on the surface; no need for secondary plastering treatment, simple clean water brushing.

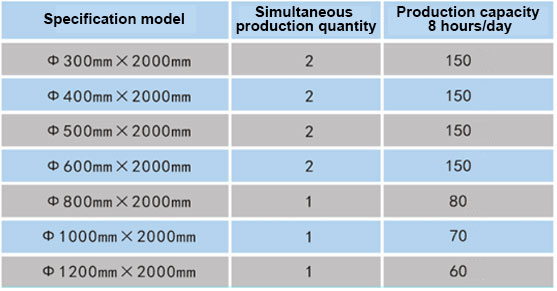

②The molding time is short due to the large excitation force; the molding time of 300-600 double tube is 4-5 minutes, and the molding time of 800-1200 single tube is 5-6 minutes.

③It can produce cement pipes with various mouths such as PVC lined pipes, glass steel pipes lined, double-steel socket pipes, and flexible A-shaped steel socket pipes.

④ No steam curing, no waste slurry; environmental protection, reduce production costs.

Because the high-frequency vibration pipe making machine uses dry hard concrete (Viber consistency 20-40S) for high-frequency vibration molding, the concrete will liquefy and gradually compact and form, and hydrothermal reaction will occur, and the internal temperature and strength of the concrete will gradually increase. High, only need to take measures to prevent moisture evaporation after forming (wrap plastic film or add plastic cover outside the tube); without steam curing, the concrete components can reach 70% strength after 3-5 days of natural curing.

Copyright © 2025 UNIQUE GROUP | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.

Product Message