How do you keep a concrete pump clean?

The importance of concrete pump cleaning

Concrete pumps will come into contact with a large amount of concrete during the construction process, if not cleaned in time, the concrete will solidify in the pump pipe, pump body and valves and other components, resulting in equipment jamming, wear and tear or even damage, affecting the service life and construction efficiency. Therefore, keeping the concrete pump clean is the key to ensure the normal operation of the equipment.

|  |

How to keep the concrete pump clean: detailed operation guide

Daily cleaning and maintenance

Cleaning immediately after pumping

After each pumping, the conveying pipeline and hopper must be cleaned immediately to prevent concrete residue curing leading to pipe blockage or component wear. Specific steps include:

Pump water or cement mortar of similar composition to concrete to remove residue in the pipe.

Disassemble the conical pipe, clean the residual concrete in the hopper with a trowel or pick out stick, and rinse the inner and outer walls with water.

Run the machine for 3-4 strokes to ensure that the water or cleaning solution is thoroughly drained from the pipe.

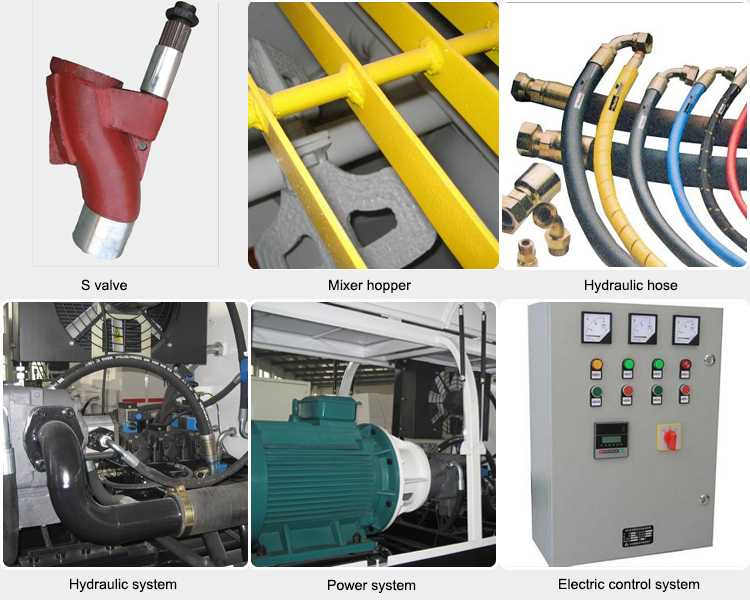

Critical Component Cleaning

Piston and water tank: Before each entry, the piston needs to be pulled back, the water tank drained of stored water, and greased and reinstalled.

S pipe valve: need to focus on flushing, otherwise the residual concrete will lead to the next pumping blockage.

Cutting ring and eye plate: check the gap (recommended <0.1mm) to ensure good sealing and avoid leakage during cleaning.

Regular deep cleaning

Water washing method: applicable to short-distance pipelines. When operating, you need to maintain sufficient water supply, pumping water until the cleaning ball emerges from the front of the pipe, taking about 10-15 minutes.

Air washing method: need to be equipped with an air compressor, pressure control within 0.8MPa, section cleaning long-distance pipeline, pay attention to safety protection.

|  |

Do I have to wash my pump parts every time I pump?

No high-pressure cleaner alternative cleaning program

Water washing combined with manual cleaning

Use ordinary water source to pump clean water continuously, with mallet to knock the pipe elbow, shock off the adherents.

Manually dismantle the end pipe, remove large pieces of residue with a shovel, and then rinse with low-pressure water.

Homemade cleaning tools

Roll a cement bag into a plunger, soak it in water and shove it into the pipe, using pumping pressure to drive the cleaning.

Use cleaning balls (need to be soaked for more than 30 minutes) with counter-pumping operation to adsorb the residue in the pipeline.

Air Washing Alternative

If the air compressor cannot be used, the pipeline can be disassembled in sections and reassembled after manual cleaning.

|  |

How do you service a concrete pump machine?

The concrete pump maintenance and troubleshooting

Common faults and maintenance methods

Plugged pipe:

Immediately reverse the concrete pump 2-3 times, suck back the concrete and remix.

Knock on the blocked part, if it is invalid, dismantle the pipe and clean it up.

Distribution valve clogging: inject cement slurry repeatedly positive and negative pump operation, or manually remove debris.

Preventive maintenance

Lubrication maintenance: Add grease to the lubrication point after each use to reduce the wear and tear of parts.

Seal check: check the cutting ring and piston seal regularly, and replace the parts with excessive wear.

Long-term out-of-service maintenance

Thoroughly clean the body before storage and apply anti-rust oil to prevent rust and corrosion.

Dismantle and maintain the key parts such as piston and S-pipe valve to ensure stable performance when it is activated next time.

|  |

Why choose our service?

Professional solutions

Provide the latest cleaning technology (e.g. water washing segment optimization, air washing pressure control) with reference to 2024 industry standards.

Customized maintenance plan to extend equipment life by more than 30%.

Efficient technical support

24-hour response mechanism to quickly solve urgent problems such as pipe blockage and slurry leakage.

Provide free operation training to ensure that users master the key points of cleaning and maintenance.

Cost-effective and environmental protection

Recommend economic cleaning program (such as homemade tools), reduce water consumption by 20%-30%.

Provide recycling service, properly dispose of waste concrete, reduce environmental pollution.

Copyright © 2025 UNIQUE GROUP | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.