As construction companies demand more and more

by:UNIQUE

2020-12-11

One of the trickiest of materials to recycle has long proved to be asphalt. Now however that isn't the case. Societe Gachet, located near Grenoble in France, is one such company who have not only encountered this problem but through working with Sandvik Mining and Construction have come up with a way to turn used asphalt into a re-usable products for sale.

Societe Gachet offers a range of materials sales, demolition and recycling services from their offices in Gillonay. From here materials are sold on to the construction industry and the company is able to produce usable products from a wide variety of construction and aggregate materials. By working alongside their Charmancon based sister company, Carriere et Voirie, they are able to provide a complete recycling service.

The key for Societe Gachet in the recycling of asphalt from road works, and other associated civil engineering projects, has been the use of some of the latest developments in mobile screening and crushing from Sandvik. They problem they faced was to crush with material down to manageable proportions for further classification. The initial steps in the process were accomplished using the QI340 ed impact crusher.

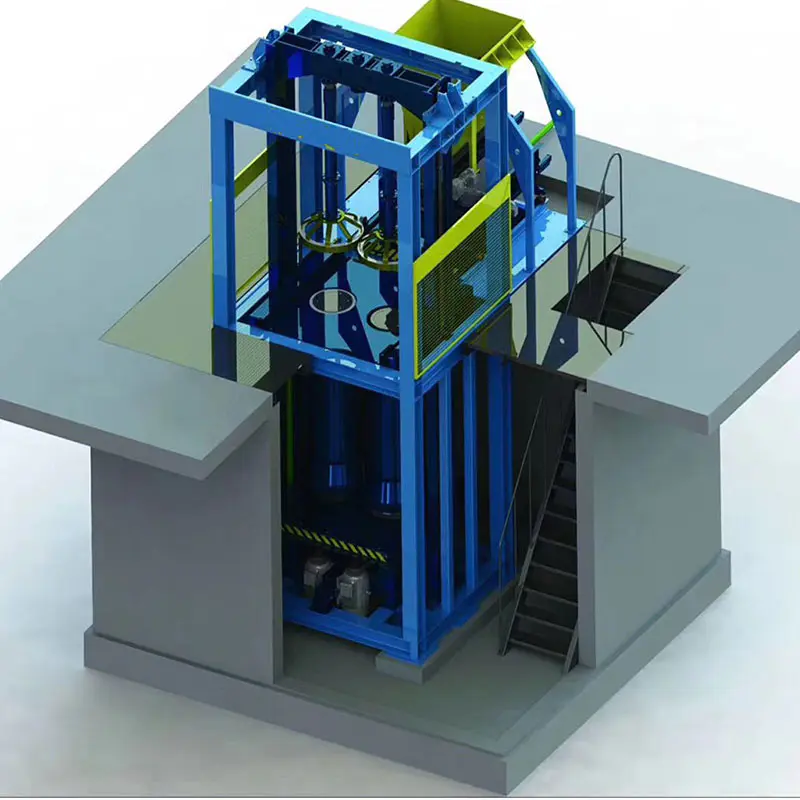

Powered by a fuel-efficient 330 kW C-13 Tier 3 compliant diesel engine, the Sandvik QI430 is carried on a manoeuvrable ed undercarriage and incorporates a Sandvik CI322 impact with a fluid clutch drive. Fed via a two-deck pre-screen, the crusher is a four hammer open-style rotor with a diameter of 1,150mm and a width of 1,330mm and discharges onto a secondary pan feeder. The plant is also equipped with a primary feeder and a separate two-deck pre-screen.

Possessing a relatively low weight and compact dimensions - the unit has an operating weight of 49.8 tonnes and is 15.5 metres in length in transport configuration - results in the QI430 being transportable in a single load, allowing it to be readily moved and redeployed for maximum utilisation. Optional equipment includes a remote diesel and water pump, an over-band magnet for recycling and demolition applications, and a dolly chassis for ease of transport.

After successfully crushing the material the asphalt was sent to the next stage of the process; screening and classifying using the Sandvik QE340. The QE340 is a heavy duty, ed, self-propelled, open flow screening and stockpiling system. This revolutionary machine has been purpose built for the recycling and quarrying markets. Based on in-depth customer and market analysis, the QE340 has been developed in order to deal with customer's real requirements, which traditional screening solutions are unable to adequately cater for.

The QE340 is based on a sturdy, crusher-type chassis and features an adjustable heavy-duty hopper, together with a double-plated apron feeder. The adjustable incline heavy-duty screen box with high throw and vibration characteristics ensures the QE340 is purpose built for arduous duties such as screening recycled asphalt.

impact crusher: http://www.hxjqchina.com/product-list_12.html

Custom message