Description

by:UNIQUE

2020-05-06

Cone Crusher uses the lubricant seal, the flaw which for the water and the drainage system has avoided to stop up disease which and incompatible easy to mix, the spring insurance system is the over-load protection, may gather the foreign matter, the iron slab through the stave cavity, but does not harm the breaker. Uses the drying oil or the water two kind of seal form, causes the stone powder and the lubricating oil isolates, guarantees reliably, the stave cavity form decides the use by the ore use. The Cone Crusher may widely apply in professions and so on metal and nonmetalliferous ore, cement plant, building, sand and crushed stone metallurgy. Is suitable in the iron ore, the non-ferrous metal ore, the granite, the limestone, the aposandstone, the sand-stone, the cobblestone and so on.

Benefits & Advantages

1. Hydraulic adjustment devices. Convenient to adjust discharge opening size.

2. Cone frame is cast steel structure; High pressure points are reinforced by hard steel

3.New special design, simple and reasonable structure, smooth and stable running and low operation cost.

4. Hydraulic release system consists of several hydraulic cylinders. Easy to release jammed materials.

5. Each side of drive-shaft is equipped with roller bearings. Bearing base uses seal ring to prevent lubricating oil leakage.

6.'Spring type' over-load protection. This release system allows unbroken materials to pass through without causing damage.

7. A complete lubricating oil circle system, including oil pump, oil reserve tank, oil pipeline, etc. If oil temperature is over high or oil flows slowly, the machine can be shut down automatically. This protection extends crushers service life.

Combined Cone Crusher Features

Industry 1st of its kind on the fly adjust for Symons cones.

Optional customer choice of adjust system from drive motor to adjust cylinders.

Hydraulic clamping without conventional cylinders.

New tramp release and clearing cylinders readily installed on either external pin or internal pin mainframes (minimum of 4' clearing built in).

Updated lube system incorporating the most reliable Viking oil pump including interface for an automated plant.

Updated hydraulic console incorporating unique manifold block, improved ease of maintenance for an automated plant.

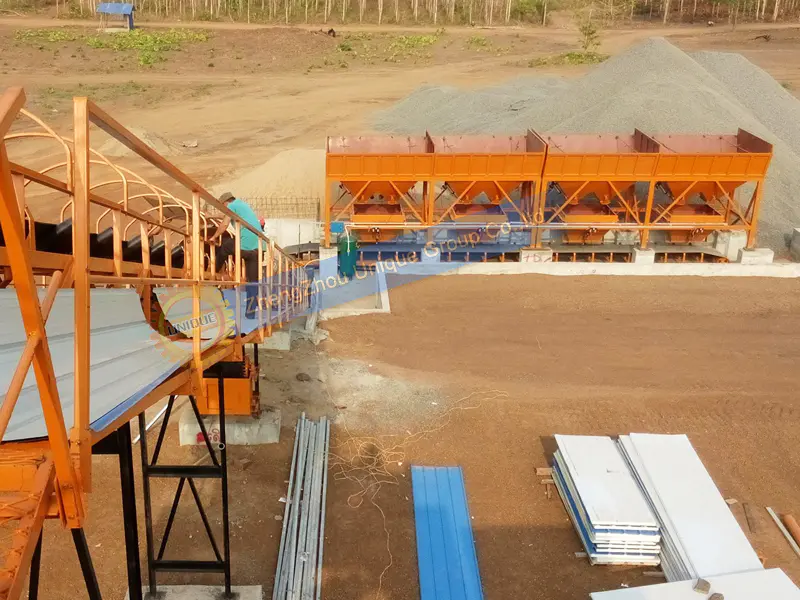

Application

combined cone crusher can be widely used in metal and nonmetal mines, cement, construction, sand and metallurgical industries. For iron ore, nonferrous metal ores, granite, limestone, quartzite, sandstone, pebbles, etc.

When cone crusher work, by the motor through V-belt, host pulley, drive shaft, a small bevel gear, bevel gear driving a large external brass rotation axis line of cone crushing force copper out by rotating the swing next move, making the broken wall near the surface from time to time and mortar wall from time to time to leave the rolling surface, so that the material in the fixed cone and fixed cone crushing cavity composed of the ring constantly under attack, pressing and bending and breaking. After repeated squeezing, shock and bending, the material crushing to the required size, the lower discharge.

As the professional manufacturer of complete sets of mining machinery, such as Artificial sand maker,VSI sand maker,Mobile crusher, Henan Hongxing is always doing the best in products and service.

Custom message