Fly ash particles. By fly ash particle morphology

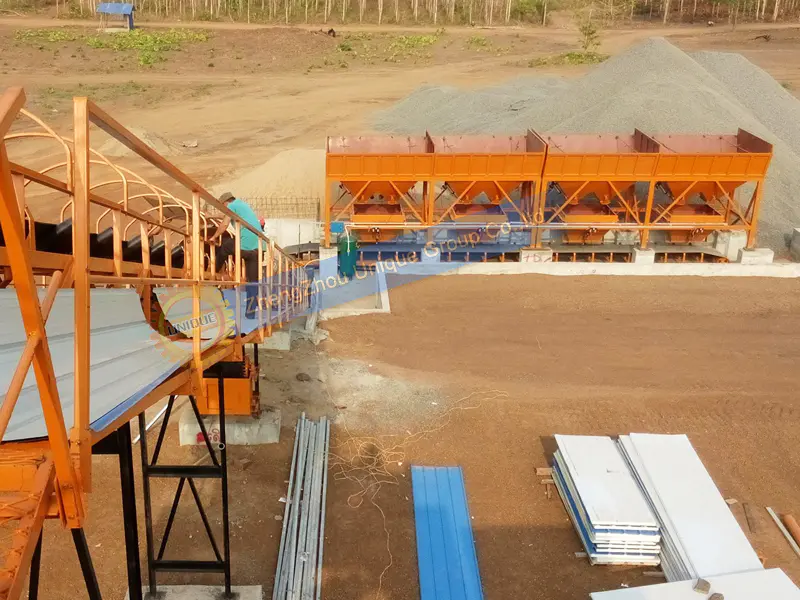

by:UNIQUE

2020-05-03

SBM Vertical roller mill fly ash after processing can be used as cement, mortar, concrete admixture, and a cement, concrete composition, fly ash as a raw material instead of clay to produce cement clinker raw materials, manufacturing sintered bricks, autoclaved aerated concrete, foam concrete, hollow brick, sintered or sintered ceramic, paving roads; to build the dam, construction of ports, potholes lowland farmland, coal mine subsidence area and backfill; can also be divided from election drift beads, beads, iron powder processing, carbon, aluminum and other useful material, including floating beads, beads can be used as insulation material, respectively, refractory materials, plastics, rubber filler.

Coal-fired boilers in power plant systems, fly ash emissions can be divided into dry and wet row row two. Currently, the cement industry in the developed regions, such as Jiangsu, Henan, Zhejiang, Hebei and other places, dry mixture of fly ash as cement material, market better, demand has shown a tendency to jump to a resource; the wet ash key physical and chemical properties with the same basic dry fly ash, water simply because a large (up to 45%), cement production can not meet the requirements of attention of the market, can only be stacked in the wet gray library, the more positive the more serious pollution of the environment. SBM continuous research and development of new technology products include: Sand, vertical crusher, compound fertilizer equipment, feeder, flotation machines and other equipment. These products have been widely used in mining, building materials, metallurgy, transportation, hydropower, coal, chemical, and environmental protection industries, not only the basis for our cause has made remarkable achievements, the development of more mining machinery industry has played a pivotal role!

The SBM R & D to create the vertical milling machine capable of solving this problem, the fly ash materials by air lock feeder feed inlet falls from the central disc, with the dryer manufacturer when the hot air from the air inlet into the mill . With the disc's rotation, the material under the action of centrifugal force, the edge of the disc moves through the ring groove on the disc by the rolling roller and crushed, crushed material in the disc edge high-speed air ring with the wind, the large SBM particle goes straight into the new grinding disc, the material flow through the upper part of the separator, the rotor rotating under the effect of meal bucket fell from the cone disc re-grinding, qualified with the powder with a mill flow through the income dust collection unit, that is, products that contain the material in the water contact with the hot air drying process is, by adjusting the air temperature, humidity materials to meet different requirements to achieve the required product water. By adjusting the separator, the product can reach the required thickness of different degrees.

With the continuous optimization of the national industrial policy, environmental regulations become increasingly harsh, the proper handling of wet fly ash has been put on the agenda. Only wet fly ash at a reasonable energy consumption, simple process for drying, so that the water is low, in order to change waste into treasure, to achieve social and economic benefits of the double harvest. Extensive use of fly ash dryer to solve the problem of pollution and fly ash disposal problem, but also fly ash waste to treasure, an increase of economic benefits.

Custom message